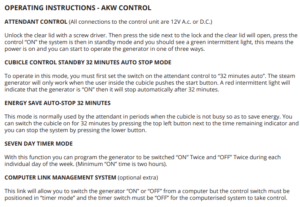

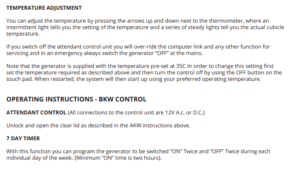

Installation Instructions

GENERAL

HNS-M2 steam generators are only intended for use in heating spa facilities. Using steam generators in other areas than steam rooms can damage the building’s structure.

The manufacturer is not responsible for damages caused if the unit has been used incorrectly or in a manner for which the unit was not designed for.

Water and steam pipe connections must be made prior to connecting the unit into the mains. Due care and attention must be taken when making the connections. Proper sealing must be ensured for all extensions. A good extension must have at least taped over threaded connections, but it is recommended that connections are soldered.

VENTILATION

It is not normally necessary to arrange ventilation for steam rooms that are used for less than two hours. Steam rooms that are used for more than two hours at a time need ventilation for functional and hygienic reasons. The ventilation recommendation is 10 to 20 m3 per person per hour.

If there is an empty space above the ceiling of the steam room, it must not be completely sealed off. Make at least one ventilation hole (100 mm x 100 mm) into the empty space, on the same wall with the door. Entry ventilation is achieved by a gap under the door.

The exit ventilation is achieved using a vent with closer at high level connected to a 100mm duct to atmosphere. Extract is not normally necessary.

SOFTENED WATER SUPPLY

In most domestic installation where the generator may be used once a day, it is not necessary to drain the tank after use. In this case a threaded nut is provided to cap off the drain valve. In cases where there the generator is fed with softened water – necessary when there is high chalk content – a stop valve should be fitted and the drain piped to waste. Alternative an automatic drain valve is available as an option.

LOCATION

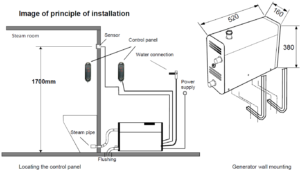

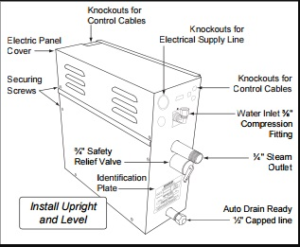

The steam generator must be placed away from water and moisture (dry room). The room must be well ventilated as the unit also produces heat. The maximum temperature of the room must not exceed 35°C. Recommended min imum free space to sides and above the steamer is 30 cm. Adequate space for maintenance should also be planned for in the placement of the unit. There should be a drain nearby for draining the tank.

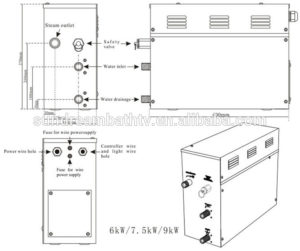

The steam generator must wall mounted using the wall brackets supplied. When using wall fittings, ensure you use appropriate fittings and screws for the type of construction material of your walls. The steam generator weighs about 17 kg when filled with water.

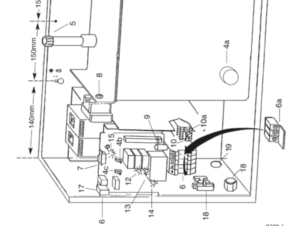

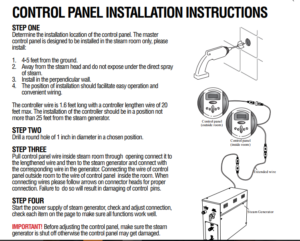

Control panel has a sensor built in to the fascia and is designed for fitting within the steam room. The control is sealed for this purpose and hard wired with connecting cable, approx. 5m. The cable of the control panel can be extended with an equivalent cable, max 10 m.

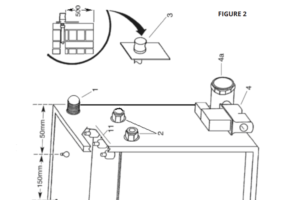

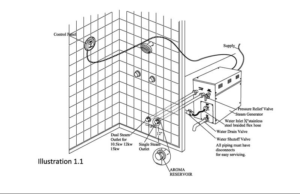

Steam nozzle is fitted approximately 300mm above floor level onto the wall so that the hot steam cannot burn anyone’s feet. The steam nozzle should be mounted with the angled slot pointing towards the floor. When the nozzle is installed, you must ensure to place such that it cannot be accidentally touched by users. The steam temperature is +100 °C and it can cause injuries on contact. If children or people with impaired reflexes use the steam room, the steam nozzle must be fitted with a protector that prevents people from being exposed to the hot steam shower.

Sensor. If the steam control is to be mounted outside the steam room a separate sensor is optionally available. Connection of this sensor on the generator circuit board automatically disables the sensor in the control fascia Sensor is installed at about 1700 mm high, preferably on the wall opposite the door. A decorative Chromed cover is provided to protect the sensor and this should be secured to the wall with sufficient silicone to seal off the cable hole, so that moisture cannot enter the wall structures.

WATER AND STEAM PIPE CONNECTIONS

Using the flexible hose supplied in the packaging the generator should be connected to mains (preferred) or stored cold water at min. 0.2 and max.10 bar. A suitable stop valve will be required. If the water pressure exceeds 3 bar an pressure reducing valve may be required to reduce noise when water is taken on.

Installation must follow local building and water authority regulations

It is recommended to use a 22mm copper pipe when connecting the steam pipe. The steam pipe diameter must be the same for the whole length. The steam pipe must be tilted upwards or downwards from the steam generator to the steam room. There MUST be NO traps in the pipe where water can collect. Any water forming in the steam pipe must be allowed to drain freely to the steam room or back to the generator. If a fragrance pump is connected to the generator, the pipe must ALWAYS drain away from the steam generator, so that the chemicals cannot enter the tank.

Recommended maximum length for the steam pipe is 5 metres.

The steam pipe should be insulated, both for safety reasons and to reduce water condensation in the pipe. Clearance from an uninsulated steam pipe to flammable material such as wood must be at least 10 mm.

WARNING: Hot steam can cause burn injuries. When using the optional auto drain valve or connecting a manual stop valve connect to the drain outlet on the generator with suitable plumbing fittings. The drain pipe must be fed to a suitable drain point (not within the steam room). Note: the temperature of the discharge water is 90–95 C.